Metal Fabrication

Precision cutting of steel plates, brackets, and custom components for structural and architectural applications with superior edge quality.

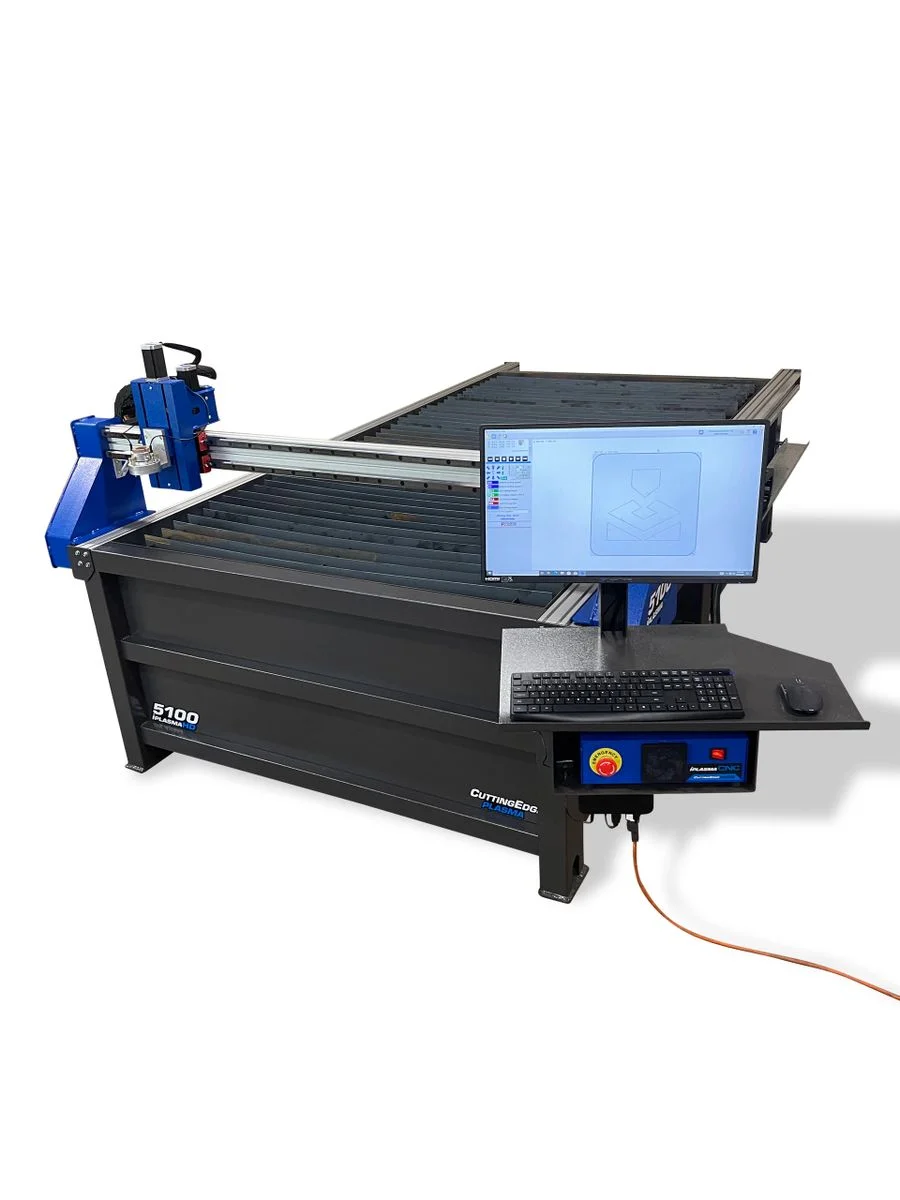

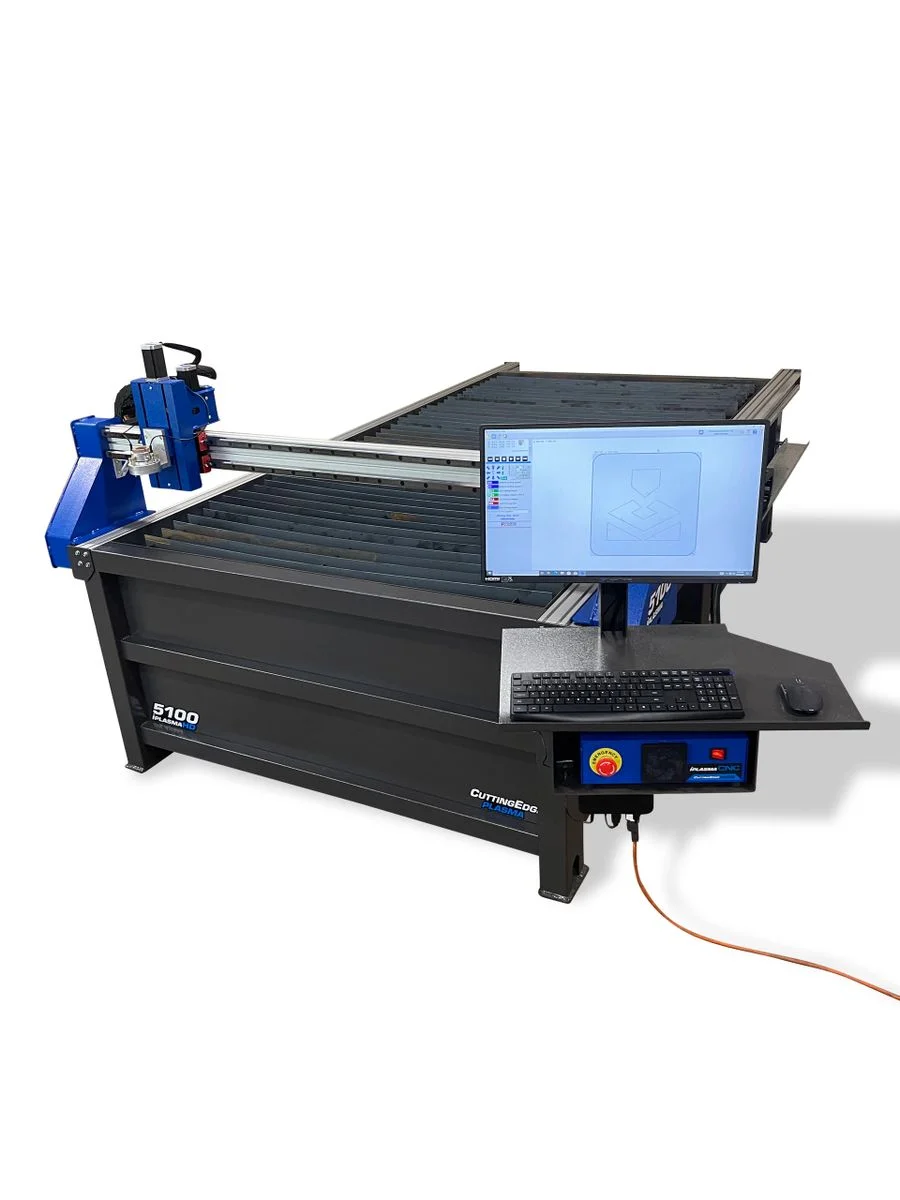

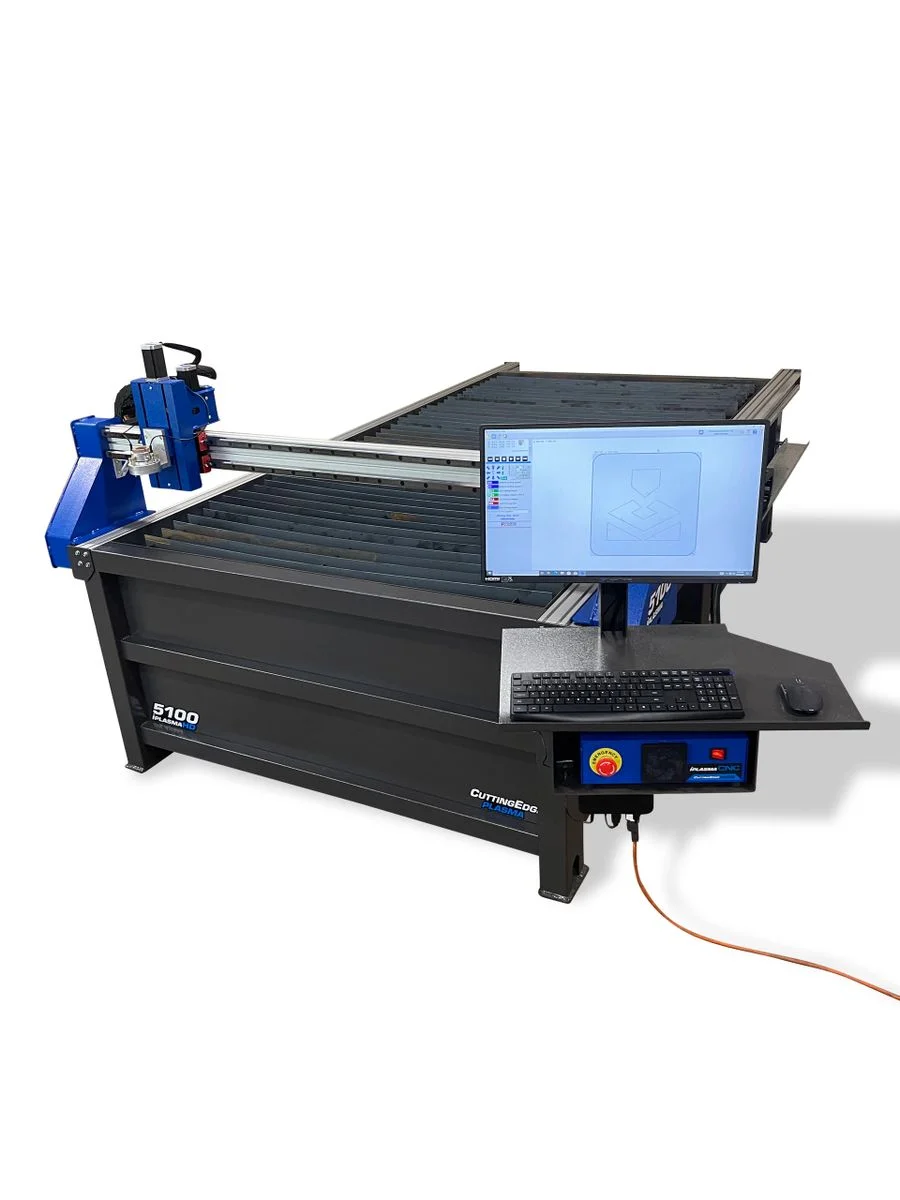

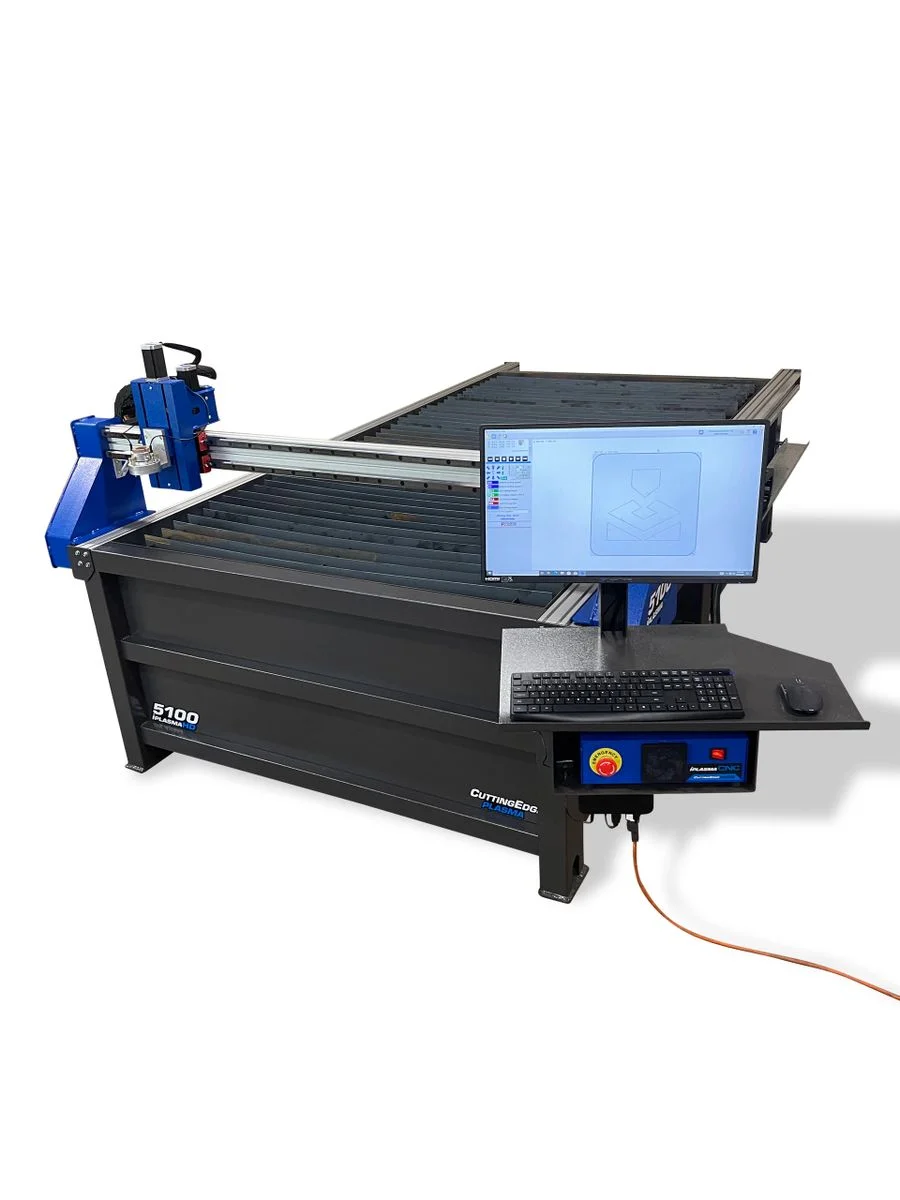

iPlasma XTREME 4400 CNC Plasma Table

Price Available on Request

Detailed specifications showcasing the industrial-grade construction and precision engineering of the iPlasma XTREME 4400.

Experience unmatched precision and reliability with advanced features designed for professional metal fabrication and industrial manufacturing.

Fully welded and powder-coated steel frame ensures maximum durability and rigidity for years of reliable operation without maintenance requirements.

5:1 planetary gear reduction units with performance Nema 34 stepper motors deliver exceptional accuracy and repeatability for complex cutting patterns.

Collision detection torch mount and proximity sensors for homing provide enhanced safety and protect your investment from accidental damage.

4" water bed design with slats effectively reduces smoke, dust, and heat distortion while improving cut quality and extending consumable life.

24" display with integrated computer and Proma controller provides intuitive operation with modern Windows 11 compatible software interface.

Convenient side loading design allows for efficient material handling and workflow optimization in your fabrication environment.

Get the latest product updates and technical resources delivered to your inbox

The iPlasma XTREME 4400 delivers precision cutting solutions for metal fabrication, manufacturing, and specialized industrial applications worldwide.

Precision cutting of steel plates, brackets, and custom components for structural and architectural applications with superior edge quality.

High-volume production of automotive parts, machinery components, and precision assemblies with consistent quality and dimensional accuracy.

Cost-effective solution for custom signage, decorative metalwork, and prototype development without the overhead of large industrial systems.

Discover how the iPlasma XTREME 4400 has transformed fabrication operations and delivered exceptional results for our customers.

The iPlasma XTREME 4400 exceeded our expectations with its robust construction and precise cutting capabilities. The fully welded frame provides the stability we need for our high-volume production runs.

Production Manager, Steel Dynamics

As a small fabrication shop, we needed a reliable CNC plasma table that wouldn't break the bank. The XTREME 4400 delivered exactly what we needed with excellent support from the Cutting Edge Plasma team.

Owner, Custom Metal Works

The lifetime technical support and direct communication with their team made all the difference. When we had questions during setup, they were there immediately to help us get running smoothly.

Shop Supervisor, Industrial Fab Co

The MyPlasma software is intuitive and the collision detection feature has saved us from costly mistakes. This machine has become the backbone of our fabrication operations.

Lead Operator, Precision Cuts LLC

We compared many options and the XTREME 4400 offered the best combination of features, quality, and price. The water bed system really makes a difference in cut quality and shop cleanliness.

Purchasing Manager, Metro Manufacturing

From delivery to first cut, everything went smoothly. The table came fully assembled and calibrated. We were up and running within hours of installation. Highly recommended for any serious fabricator.

Operations Director, Apex Metalworks

Discover our full range of precision CNC plasma tables designed to meet diverse fabrication needs and budget requirements.

Features fully welded powder-coated frame with Nema 23 stepper motors, V-rail system on 3"x3" beam, and 6" travel ball screw for reliable entry-level precision cutting applications.

Advanced CNC plasma table with fully welded frame, performance Nema 34 stepper motors, dual rigid rail on 3"x6" beam, and enhanced SG-35 speed guide rail system for maximum precision.

Professional-grade CNC plasma table featuring fully welded powder-coated frame, performance Nema 34 stepper motors, dual rigid rail system, and 8" travel ball screw for demanding applications.

Our experts will help you select the perfect CNC plasma table for your specific cutting requirements and budget.

Get in touch with our team to discuss your CNC plasma cutting needs and discover how the iPlasma XTREME 4400 can enhance your operations.

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com