Metal Fabrication

Precision cutting of steel plates, brackets, and structural components for construction and manufacturing industries.

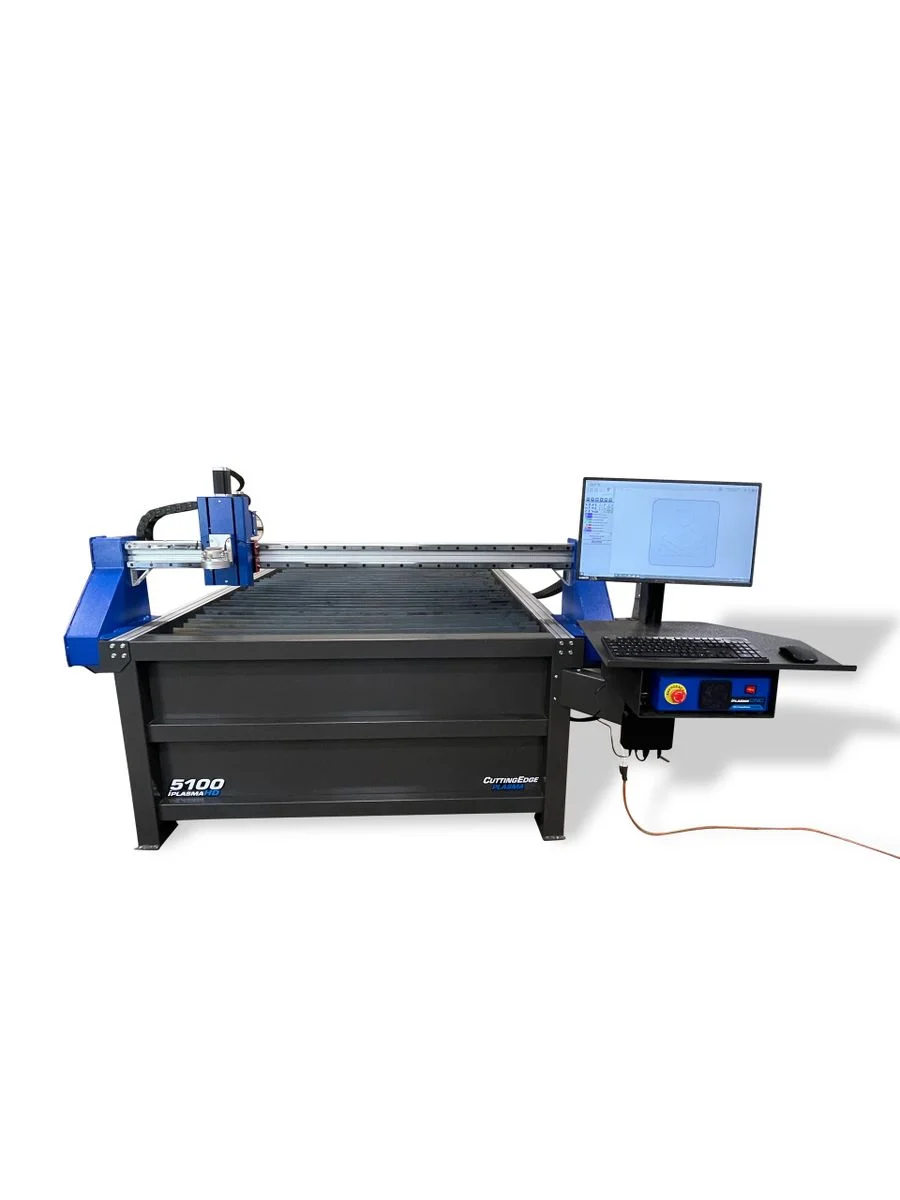

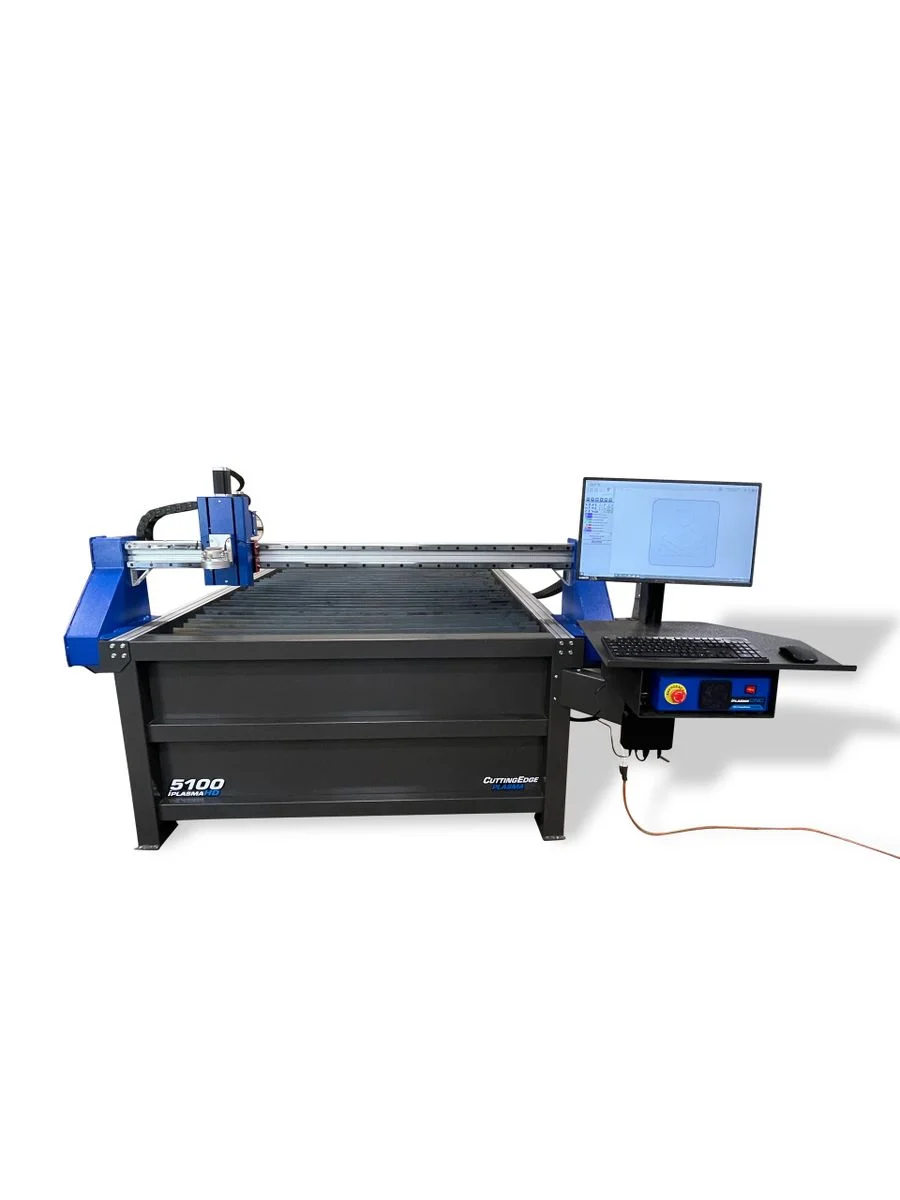

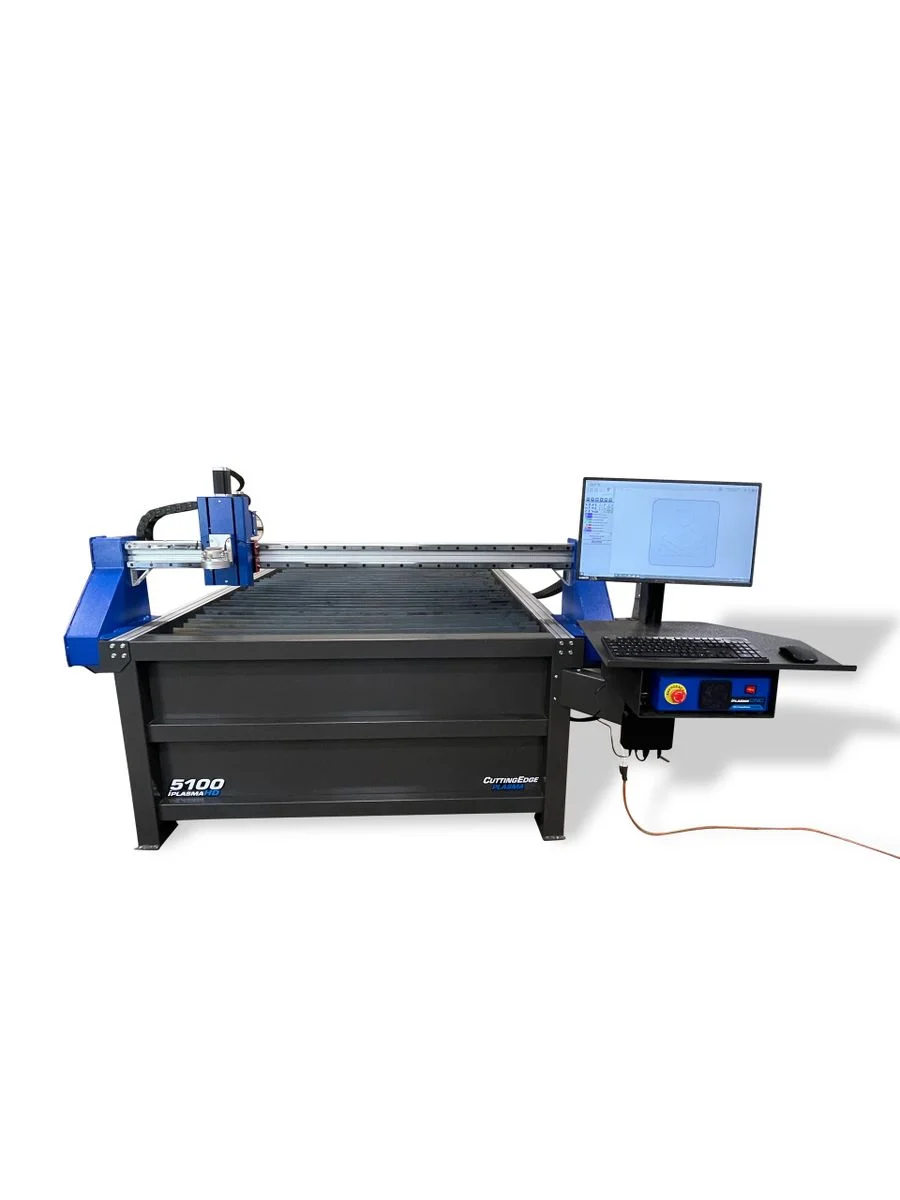

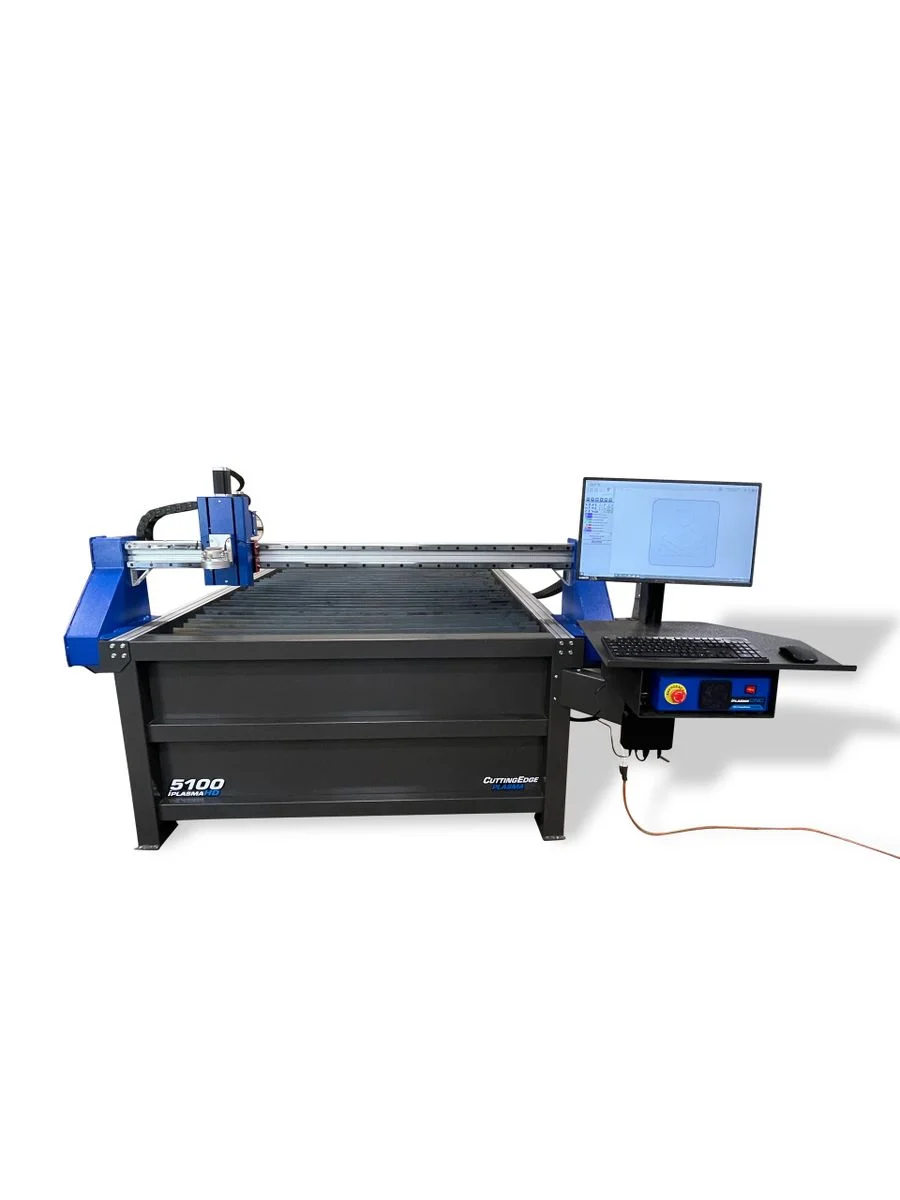

iPlasma PRO 4400 CNC Plasma Table

Price Available on Request

Detailed specifications for the iPlasma PRO 4400 CNC Plasma Table engineered for precision cutting applications.

Experience superior cutting precision and reliability with advanced engineering and innovative design features.

Fully welded steel frame with powder coating ensures maximum rigidity and durability for consistent, accurate cuts every time.

5:1 planetary gear reduction units with Nema 23 stepper motors deliver smooth, precise movement for superior cutting performance.

Collision detection torch mount and proximity sensors for homing provide automated safety features that protect your equipment and workpieces.

Integrated 24" display with computer system and Proma controller standard makes operation intuitive and efficient for all skill levels.

4" water bed design significantly reduces smoke and dust during cutting operations, creating a cleaner and safer work environment.

Robust construction with quality components means minimal maintenance requirements and maximum uptime for your manufacturing operations.

Get product updates, technical tips, and exclusive offers delivered to your inbox.

The iPlasma PRO 4400 serves diverse manufacturing needs from metal fabrication shops to custom automotive parts production.

Precision cutting of steel plates, brackets, and structural components for construction and manufacturing industries.

Custom automotive parts, brackets, exhaust components, and restoration pieces requiring precise metal cutting capabilities.

Ductwork, ventilation components, and custom heating system parts requiring accurate cutting of various metal thicknesses.

Artistic metalwork, decorative panels, sculptures, and custom artistic projects requiring intricate cutting patterns and designs.

Farm equipment parts, implement attachments, and agricultural machinery components requiring durable and precise metal cutting.

Hear from manufacturers who've transformed their operations with our CNC plasma tables and experienced exceptional results.

The fully welded frame construction gives us the rigidity we need for precision cuts. The water bed system keeps our shop much cleaner than our old dry table.

Shop Owner, Steel Works Inc.

As a small fabrication shop, this table gave us the precision we needed without breaking the bank. The support from Cutting Edge Plasma has been exceptional.

Owner, Precision Metal Works

The MyPlasma software is intuitive and the machine came ready to run. No assembly headaches like other brands. Highly recommend for anyone serious about plasma cutting.

Production Manager, Custom Automotive

We needed professional-grade cutting capability without the industrial price tag. This table delivers consistent results and the lifetime support gives us confidence.

Operations Director, Metro Fabrication

Running this table daily for over a year with minimal maintenance required. The collision detection has saved us from several costly mistakes already.

Lead Fabricator, Industrial Solutions

Started as a hobbyist and this table helped me transition to professional work. The quality and precision allowed me to take on commercial projects with confidence.

Owner, Custom Metal Creations

Discover our complete range of precision CNC plasma cutting solutions designed for every application and budget requirement.

Enhanced performance with Nema 34 stepper motors, 30 MM dual rigid rail system, and 8" travel ball screw for superior precision and speed in demanding applications.

Large format cutting table with performance Nema 34 motors, dual rigid rail system, and advanced SG-35 speed guide rail for maximum cutting area and precision.

Mid-size professional table featuring Nema 34 stepper motors, dual rigid rail construction, and 8" travel ball screw for versatile cutting applications.

Our experts can help you choose the perfect CNC plasma table for your specific requirements and budget.

Ready to transform your metal fabrication capabilities? Contact our team for personalized recommendations and competitive pricing on CNC plasma tables.

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com