Metal Fabrication

Ideal for structural steel cutting, pipe cutting, and general fabrication work with superior edge quality and minimal preparation time.

Hypertherm Powermax125 CSA 480V Machine System

Price Available on Request

Comprehensive technical specifications for the Hypertherm Powermax125 plasma cutting system.

Experience superior cutting capabilities with advanced technology features designed to maximize productivity and cut quality.

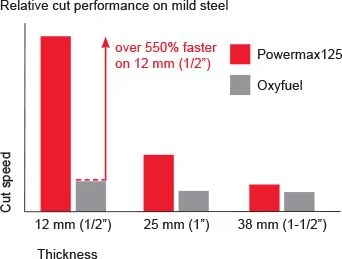

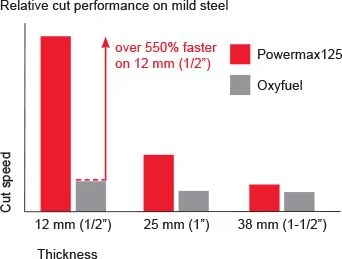

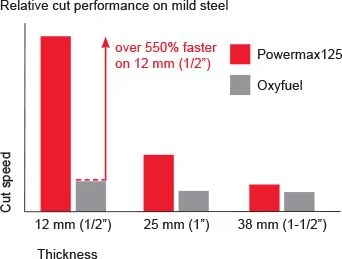

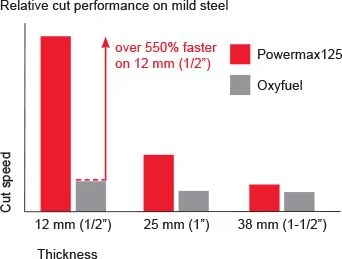

Finish jobs faster with cut speeds five times greater than oxyfuel on 12 mm (1/2") mild steel, maximizing your operational efficiency.

Achieve excellent cut and gouge quality that reduces grinding and edge preparation time, saving you valuable resources.

Maximize cutting time with continuous operation capability, ensuring uninterrupted workflow for demanding applications.

No need to change air pressure manually - Smart Sense™ technology automatically ensures correct pressure settings for optimal performance.

End-of-life detection automatically stops power when the electrode is overused, protecting both torch and workpiece from damage.

Hypertherm Certified™ reliability ensures peak performance even in the harshest industrial environments with Duramax Hyamp torches.

Stay informed with the latest plasma cutting innovations and technical documentation.

Discover how the Powermax125 delivers exceptional performance across diverse industrial applications and cutting requirements.

Ideal for structural steel cutting, pipe cutting, and general fabrication work with superior edge quality and minimal preparation time.

Perfect for heavy plate cutting in marine construction with high-speed processing and excellent cut quality on thick materials.

Essential for construction projects requiring precise cuts on structural materials with reliable performance in harsh environments.

Supports automotive manufacturing with precision cutting capabilities for chassis components and body panels with consistent quality.

Excellent for on-site maintenance and repair operations with portable automation capabilities and versatile torch options.

Discover how the Powermax125 has transformed cutting operations for businesses worldwide with superior performance and reliability.

The Powermax125 has revolutionized our cutting operations. The speed and quality are unmatched, and the Smart Sense technology eliminates guesswork.

Operations Manager, Steel Dynamics Inc.

The 100% duty cycle and electrode protection have significantly reduced our downtime. It's built to handle our toughest jobs day after day.

Production Supervisor, Atlantic Shipyard

The cut quality is outstanding - minimal grinding needed and the drag cutting feature with dross reduction saves us hours of finishing work.

Shop Foreman, Precision Metal Works

The consumable life is incredible - up to four times longer than our previous system. The ROI has exceeded our expectations completely.

Plant Manager, Industrial Fabricators

The multiple torch options make this system incredibly versatile. We use it for everything from hand cutting to automated operations seamlessly.

Technical Director, Custom Steel Solutions

Hypertherm's reputation speaks for itself. The SpringStart technology ensures consistent performance and the reliability is exactly what we needed.

Quality Manager, Apex Manufacturing

Discover our comprehensive range of Hypertherm plasma cutting systems designed to meet diverse industrial cutting requirements and applications.

Advanced SYNC system featuring CPC port connectivity, 180 degree machine torch with 25' lead, and revolutionary cartridge reader technology for automated consumable detection and performance optimization.

Professional industrial plasma cutting system featuring advanced SYNC technology and precision machine torch capability for demanding industrial applications requiring consistent high-quality cuts.

Compact SYNC system with Duramax Lock handheld torch featuring 75° torch head and 6.1m (20') lead, essential mechanized consumable kit, and complimentary shipping for complete value.

Our experts can help you select the perfect plasma cutting system for your specific applications and requirements.

Contact our team today to learn more about the Hypertherm Powermax125 and discover how it can revolutionize your plasma cutting capabilities.

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com

For immediate assistance, call (952) 500-3353 or email us at steve@cuttingedgeplasma.com